Composition of electrolyte for batteries

For modern acid accumulators, the main medium in which the reactions occur is the electrolyte. From its amount, temperature, electrochemical characteristics, the work of the entire battery fully depends. For each season, the composition of the electrolyte for batteries must have a certain density. This will provide the duration and correctness of its operation.

In the serviced batteries, you can control the composition and density of this fluid. This operation is performed using a specific set of tools.

The main components of which consists of electrolyte, are familiar even to a schoolboy. Therefore, the answer to the question of which acid in the car battery is "concentrated sulfuric acid". To ensure the operation of the automotive battery, it is diluted with distilled water.

The maximum value of the acid density is 1.84 g / ml. However, motorists more often use the diluted fluid having an indicator of 1.4 g / cm 3. In the process of dilution of sulfuric acid, a lot of heat is highlighted.

Work with electrolyte

It is necessary to know that acid solutions that have a very high degree of purification from unwanted impurities are used for batteries.

The parameters that the acid must correspond are even described in state standards GOST 667-73. This is due to the fact that garbage impurities significantly reduce the service life of the electrical appliance.

The main criterion for which solutions is distinguished between themselves is the density of the liquid. It is necessary that this parameter does not go beyond 1.07 ... 1.3 g / ml. Such results provide an approximate content of H 2 SO 4 concentrate at 27-40% in solution.

It is necessary to know that in the reference books of the testimony of acid in the solution is most often indicated at 15 C. When the ambient temperature changes, it is necessary to include the correction temperature coefficient.

Electrolyte checking in batteries

This operation must be carried out at least twice a year: with the beginning of the onset of cold weather and when establishing summer warm weather. It is precisely the change of temperature should be decisive at the beginning of the inspection.

Working is carried out in the presence of such auxiliary set:

- the range is a device with which the density of fluids is checked (it is easy to find in almost any auto shop);

- a glass tube with an inner diameter of 5-7 mm (in some cases it will replace the blank sheet of paper).

Car Aareometer

The preparation of the electrolyte for batteries begins with checking the current state of the fluid in all banks. To do this, you can apply a simple algorithm:

- in serviced batteries, the cork is unscrewed from the test bank;

- shallowly immersed the working part of the range in the tank with electrolyte;

- with the help of rubber pear on the area, we draw a small amount of fluid in the area so that the float goes into the raised state and float, without touching the walls of the vessel;

- on the contact line of the electrolyte and the rod will be real density data;

- record the result on the sheet of paper.

We carry out the measurement procedure for each container separately.

You need to know that the density values \u200b\u200bin all banks must be as close as possible and must differ from each other by more than 0.2-0.3 g / cm 3.

Lack of density can be compensated for by a higher level of charge. This will provide a larger density rate, and, accordingly, a lower temperature of the freezing of the liquid.

In addition to density, the driver during the operation of the car is obliged to maintain the sufficient level of fluid in the battery. Lower it lower than 10-15 mm above the top level of the plates is not recommended.

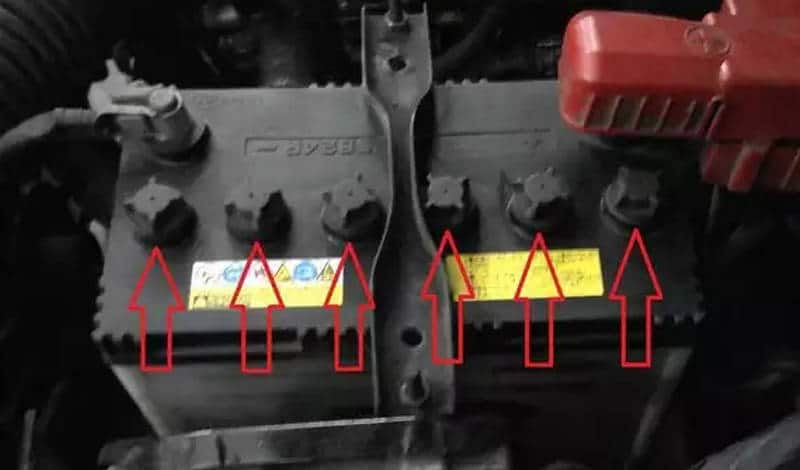

Liquid level in battery

Level measurements are easy to perform with a glass tube on an accumulator smooth horizontally installed. To do this, omit it into the selected jar so that the bottom end of it concerned the top of the plates. After that, we close a tight open end of the tube with your finger, so that the fluid leakage does not occur from the cavity of the tube. We measure the resulting level with any ruler.

When identifying an insufficient amount of fluid, it is necessary to add distillates in a problem can be addressed in several ways. During the procedure there will be a small allocation of heat or boiling.

It is necessary to know that in no case cannot be carried out at the electrolyte battery to bring the fluid to the required level. This action you can spoil the battery.

Checking the electrolyte with a glass tube

Checking the level in the absence of a glass tube is allowed to be carried out with a pure paper sheet, rolled into a small pipe. The procedure will be the same, but it should be noted that in this case the wetting will show a slightly greater level of electrolyte due to the measurement error.

Electrolyte parameters in different temperature conditions

For each season or climatic zones, the corresponding electrolyte parameters for density are withstanding.

It is necessary to know that for winter conditions and cooler climatic zones, the electrolyte density should be higher, as this will provide a significant decrease in the freezing temperature of this fluid.

In hot climatic zones and during the warm temperature mode of the environment, it is desirable to maintain a smaller density of electrolyte, as it provides a much longer battery life.

The correct parameters can be supported thanks to a special table that defines a favorable density for the season and climatic conditions. In severe conditions, and with an extreme decrease in temperature, it is recommended to make an acb into a warm room. It is also possible to carry out its refreshing and checking the electrochemical parameters.

Corks in the serviced battery

At a low density at the level of 1.1 g / ml, the liquid is already capable of the appearance of ice crystals even at -6 C. Therefore, even for ride in the frost, motorists of the northern regions use special thermocontainers protecting AKB.

Preparation of electrolyte

In auto shops, new batteries are offered for sale already flooded with the necessary amount of prepared liquid. However, there are instances requiring refueling, dried acb. This option will be more appropriate for extreme climatic zones requiring an individual approach in the preparation of electrolyte. For novice motorists, the most advantageous option will be the purchase of already prepared fluid for specific climatic zones.

If it is not possible to choose a finished volume, then you can create a solution under your conditions yourself. Necessary attributes:

- capacity with distilled water, which can be found either in a pharmacy or in a car shop;

- acid H 2 SO 4 (sulfur) with a density level of 1.4 g / cm 3 (the preferred indicator) or 1.84 g / cm 3 (used in extreme cases);

- capacity with which it will be possible to measure the required amount of fluid to work;

- tube or rod from chemically neutral materials (ebonite, glass, ceramics) for mixing the solution;

- individual protection elements (glasses, high-quality rubber gloves, protective apron, jacket with long sleeves).

When working with chemical reagents, you need to comply with some rules:

- it is forbidden to pour water into acid, especially sharp movement, as this leads to splashing and occurrence of chemical burns;

- it is allowed to topping the acid into water with a thin jet;

- during the topping, it is necessary to make mixing with a tube or an ebonite stick.

After making the necessary doses, it is necessary to measure the density with the help of the area.

During the preparation of electrolyte, you need to know the required amount of fluid in the battery. The volume in different models varies in the range of 2.6 ... 3.7 liters. To replace, you can prepare a liquid with a margin, and the residues are disposed of with food soda.

There are certain proportions to prepare a solution of a given density. Introductory data is a proportional amount of acid and distillate.

Refueling electrolyte

You need to fill the prepared liquid very carefully. This is done with a glass funnel or from a different chemically neutral material. A glass mug with a special bent nose is suitable.

The operation is carried out until the fluid rises above the plates in banks by 10-15 mm. Next, leave the entire system for 2-3 hours alone. After that time, the density of the medium may slightly fall, which is a permissible phenomenon.

Charging AKB

The filled battery must be charged to the operating mode. For this operation, a current is used, which is 10 times less than the value indicated as a container on the battery case. This means that for the readings outside the battery 60 a * h, the current of the current in 6 A. Charging should be continued for 4 hours. After that, the density and level of fluid is measured again. Electrical appliance is prepared for work.

Possible difficulties in work

The car battery during operation can fall into different situations, for example, in its body the electrolyte will begin to freeze and crystallize. No burners in this case cannot be used. It is enough to turn it off from the electrical wiring and put into the warm room for 12-20 hours. This procedure will ensure uniform thawing of all cold tanks.

If the driver noticed cracks that arose from freezing or for other reasons, then such a battery is not subject to further operation. It must be disconnected from the terminals and immediately get from the workpiece.

When the case is blown without damage, you can be charged for charging, adjusting the charger for the flow of current to 1 A for a period of about 1 day.

Frozen battery

It will take several times to monitor the density of the electrolyte. With a noticeable increase in density during charging, you need to know that the battery will be able to serve some more time.

Separate copies of the AKB with a significant discharge do not gain the desired container during charging. A complete electrolyte replacement is allowed in all tanks. Pre-banks are squinted with distilled water before the prepared solution of the prepared solution. Then leave the battery for a couple of hours for impregnation of the plates, and after they put for two days to charge the current from the sex amp to 1 amp. The procedure is completed after the density does not change within 2 hours.

Conclusion

The amount and quality of the electrolyte affects the operation of the battery. The density readings in the batteries served are controlled by a minimum twice per year. If the fluid level in banks falls, then it is necessary to top up distilled water. When buying an acb with dry charging, it is also desirable to purchase a prepared solution from well-known manufacturers using high cleaning acid. During self-preparation, it is necessary to comply with all individual safety measures.