Supply system

The main elements that are nozzles.

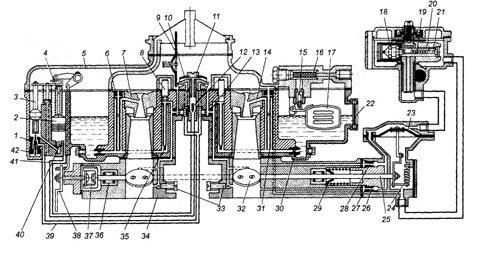

The carburetor motor system includes: Fuel tank, filter-settling, fueling, fuel pump, fuel purification filter, air cleaner, intake pipe wire, exhaust pipe, receiving pipes, silencer, fuel level control devices.

Working system

When working the engine The fuel pump sucks fuel from the fuel tank and through the filters serves a carburetor in the float chamber. When the inlet tact in the engine cylinder is created a vacuum and air, passing through the air cleaner, enters the carburetor, where it is mixed with fuel pairs and in the form of a combustible mixture is supplied to the cylinder, and there, mixed with exhaust gas remains, a working mixture is formed. After completing the working stroke, the exhaust gases are pushed out by the piston in the exhaust pipeline and at the receiving pipes through the silencer in the surrounding medium.

|

Device TNVD YAMZ |

Power supply systems and exhaust gases of a car engine:

1 - air flow channel to the air filter; 2 - air filter; 3 - carburetor; 4 - handle of manual air damper control; 5 - manual control handle throttle; 6 - throttle control pedal; 7 - Fuel Wires; 8 - filter-sump; 9 - silencer; 10 - receiving pipes; 11 - exhaust pipeline; 12 - Filter of fine fuel purification; 13 - fuel pump; 14 - fuel level index; 15 - fuel level indicator sensor; 16 - fuel tank; 17- Cover of the neck of the fuel tank; 18 - Crane; 19 - graduation tube of the muffler.

Fuel. As fuel in carburetor engines, gasoline is usually used, which is obtained as a result of oil refining.

Automotive gasoline, depending on the number of easily evaporating fractions, are divided into summer and winter.

For automotive carburetor engines, gasoline A-76, AI-92, AI-98, etc., and others are produced. The letter "A" indicates that the automotive gasoline, the figure is the smallest octane number characterizing the detonation resistance of gasoline. Isoattan has the largest detonation resistance, (its post-bone is taken for 100), the smallest - n-heptane (its resistance is 0). A octane number characterizing the detonation resistance of benzi-on, - the percentage of isochastane in such a mixture with a n-heptane, which is equivalent to the fuel to the tested fuel. For example, the fuel under study detonates the same way as a mixture of 76% iso-octane and 24% H-heptane. The octane number of this fuel is 76. The octane number is determined by two methods: Motor and Research-Telsky. When determining the octane number, the letter "and" is added to the second method in the gasoline brand. The octane number determines the pre-letm of compression.

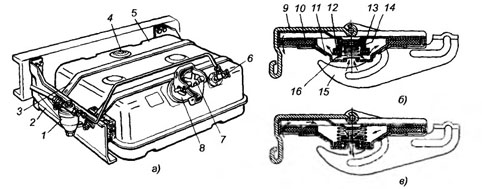

Fuel tank. On the car install one or more fuel tanks. The volume of the fuel tank must provide 400-600 km of the car's mileage without refueling. The fuel tank consists of two welded halves made by a stamping from a wicked steel. Inside the tank there are partitions that give the stiffness of the design and prevent the formation of waves in the fuel. At the top of the tank, a bulk neck is welded, which is closed by a plug. Sometimes for the convenience of refueling the fuel fuel, a retractable neck with a mesh filter is used. On the upper wall of the tank, the fuel level indicator sensor and the fuel is the intake tube with a mesh filter. In the bottom of the tank there is a threaded hole for draining the sludge and removal of mechanical impurities, which is closed by a plug. The filling neck of the tank is closed with a tight plug, in the housing of which there are two valves - steam and air. A steam valve, when improving pressure in the tank, opens and displays steam into the environment. The air valve opens when fuel consumption and vacuum is created.

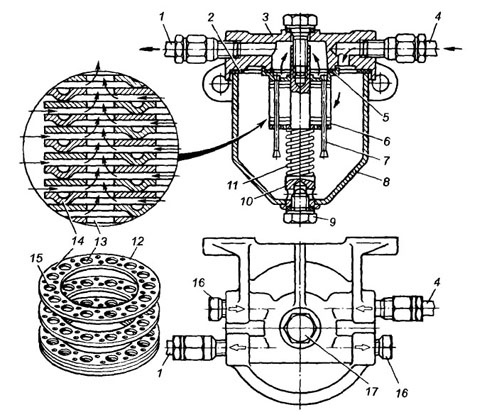

Fuel filters. To clean the fuel from mechanical impurities, filters are used coarse and fine cleaning. Filter-sump rough cleaning separates fuel from water and large mechanical impurities. The filter-sump consists of a housing, a sump and filtering element, which is collected from plates with a thickness of 0.14 mm. On the plates there are holes and protrusions with a height of 0.05 mm. The plate package is mounted on the rod and spring is pressed to the housing. In the assembled state between the plates there are cracks through which fuel passes. Large mechanical impurities and water are collected at the bottom of the sump and through the plug hole in the bottom periodically removed.

Fuel tank (s) and production of graduation (b) and intake (c) valves: 1- filter-sump; 2 - Bracket attachment bracket; 3 - tank fastening clamp; 4 - fuel level sensor in the tank; 5 - fuel tank; 6 - crane; 7 - tank tube; 8 - neck; 9 - Cork cladding; 10 - rubber gasket; P - cork housing; 12 - exhaust valve; 13 - Spring of the exhaust valve; 14 - inlet valve; 15 - tank tube lever; 16-Spring inlet valve.

Filter-sump: 1 - fuel wire to the fuel pump; 2 - enclosure laying; 3 - body cover; 4 - fuel wire from the fuel tank; 5 - laying of the filter element; 6 - filter element; 7-rack; 8 - sump; 9- drain plug; 10 - the rod of the filter element; 11 - Spring; 12 - plate of the filter element; 13 - hole in the plate for the passage of purified fuel; 14 - protrusions on the plate; 15 - hole in the plate for racks; 16 - plug; 17 - bolt fastening of body cover.

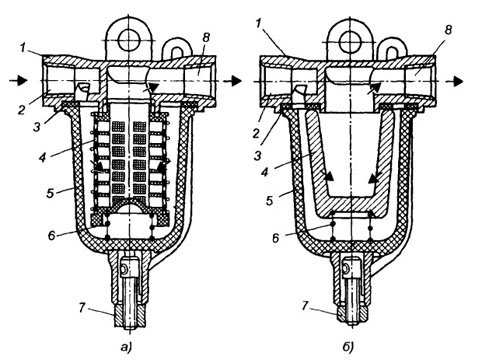

Filters of fine fuel filtering with filter elements: a - mesh; b - ceramic; 1- Corps; 2-inlet; 3- gasket; 4- filter element; 5-removable glass-sump; 6 - spring; 7-screw fastening of a glass; 8- Channel for fuel removal.

Filter of fine cleaning.

To clean the fuel from small mechanical impurities, filters of fine cleaning are used, which consist of a housing, a glass-sump and a filter mesh or ceramic element. Ceramic filter element is a porous material that provides the labyrinth movement of fuel. The filter is held by a bracket and a screw.

Fuel Wires join the fuel system devices and are made of copper, brass and steel tubes.

Fuel pump power supply pump

The fuel pump serves to supply fuel through the tank filters to the carburetor float chamber. Apply a diaphragm type pumps with a drive from the camshaft eccentric. The pump consists of a housing in which the drive is attached is a biscuit lever with a spring, heads where inlet and discharge valves with springs and covers are placed. The edges of the diaphragm are clamped between the housing and head. The rod of the diaphragm to the drive lever is attached to be hinged, which allows the diaphragm to work with variable strokes.

When the biscuit lever (rocker) lowers the diaphragm down, the cavity above the diaphragm creates a vacuum, due to which the inlet valve opens and the nadiaphraggment cavity is filled with fuel. When running around the lever (pusher), the aperture rises up under the action of a return spring. Over the diaphragm, the pressure of the fuel is increased, the intake valve is closed, the injection valve opens and the fuel is opened through the fountal filter into the float chamber of the carburetor. When changing the filters, the float chamber is filled with fuel using the device for manual swap. In the case of the output of the diaphragm (crack, breakthrough, etc.), the fuel enters the lower part of the housing and flows through the control hole.

Air filter It serves to clean the air entering the carburetor, from dust. Dust contains the smallest quartz crystals, which, settled on the smeared surfaces of parts, causes their wear.

|

|

Requirements for filters:

. air purification efficiency from dust;

. Small hydraulic resistance;

. Sufficient digestibility:

. reliability;

. convenience in maintenance;

. Technological design.

By way of cleaning air, filters are divided into inertia and dry.

Inertia and oil filter It consists of a housing with an oil bath, covers, air intake and a filter element from synthetic material.

When the engine is operating, air passing through the ring gap inside the housing and, in contact with the surface of the oil, changes the direction of movement sharply. As a result, large dust particles in the air stick to the surface of the oil. Then the air passes through the filter element, is cleared of small dust particles and enters the carburetor. Thus, the air passes two-stage cleaning. When clogged, the filter is washed.

Dry air filter It consists of a housing, covers, air intake and a filtering element from porous cardboard. If necessary, the filter element is changed.