Hydrogen engine: principle of operation and device

As is known, the piston internal combustion engine has both pros and a number of certain deficiencies. First of all, the global problem is toxic exhaust, as well as the constant need for petroleum fuel. The situation is not much changed after the transfer of the car for gas, as it also does not solve all tasks.

Taking into account these features, alternative options are constantly being developed. Today, the real competitor is the electric motor. At the same time, a relatively small stroke, the high cost of batteries and in total, as well as the lack of a developed infrastructure for the repair and maintenance of such machines naturally slows down their popularization.

For this reason, automakers are constantly working to get "harmless" to the environment and relatively cheap in the production of a power unit, which will not need an expensive fuel.

Among such engines, hydrogen-in-law should be isolated separately, which may well replace the existing diesel or gasoline engine, and in the foreseeable perspective. Let's look at how the hydrogen engine works, what kind of design has a similar motor and what is its features.

Read in this article

History of creating a hydrogen engine

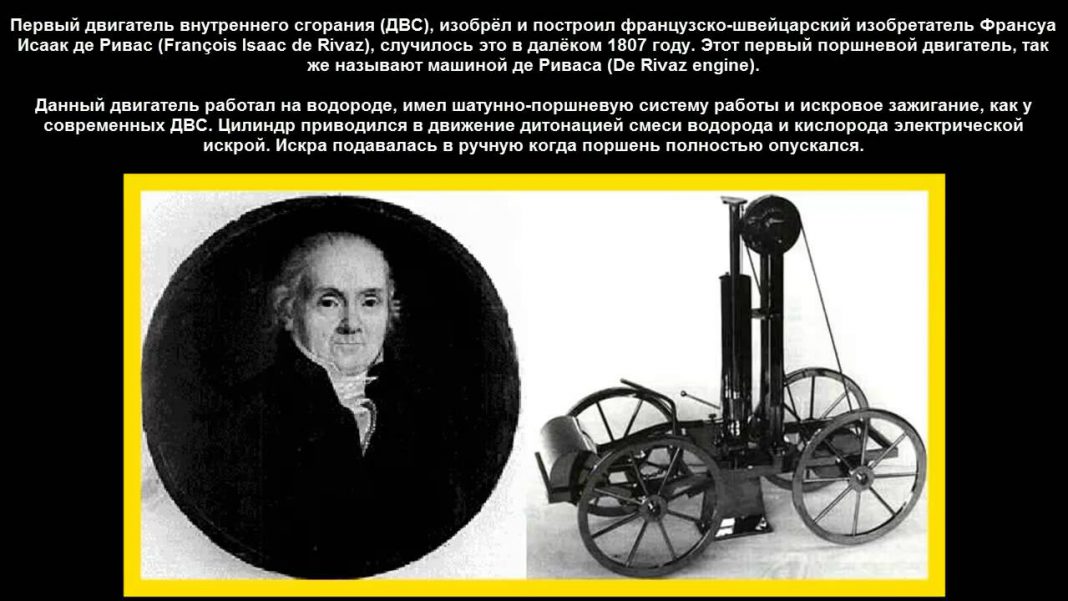

Let's start with the ideas to build a hydrogen engine appeared in 1806. The founder became Francois Isaac de Rivaz, which received hydrogen from the water by the electrolysis method. As can be seen, the engine on hydrogen "was born" long before a number of questions were raised regarding the environment and exhaust toxicity.

In other words, attempts to launch the DVS on hydrogen were undertaken not to protect the environment, but in order to banal use of hydrogen as fuel. After several decades (in 1841), a first patent for such an engine was issued, in 1852 an aggregate appeared in Germany, which successfully worked on the mixture of air and hydrogen.

During the Second World War, when difficulties arose with the supply of petroleum fuel, technician from the USSR Boris Isaakovich Shelisch, who was from Ukraine, laid the foundations of the Russian hydrogen energy. He also suggested using a mixture of hydrogen and air as a fuel for the OI, after which his ideas quickly found practical application. As a result, there were about half a hundred engines worked on hydrogen.

However, after the end of the war, the further development of the hydrogen engine was suspended both in the USSR and around the world. Then the engine was remembered only when a fuel crisis happened in the 70s of the 20th century. As a result, BMW in 1979 built a car whose engine was used by hydrogen as the main fuel. The unit worked relatively stable, there were no explosions and emissions of water vapor.

Other automakers also started work in this area, as a result of which, by the end of the 20th century, not only many prototypes appeared, but also quite successfully operating samples of engines on hydrogen fuel (gasoline and diesel engine on hydrogen).

However, after the fuel crisis has ended, work on hydrogen FCs was also minimized. Today, interest in alternative energy sources is growing again, now because of serious environmental problems, as well as taking into account the fact that oil reserves on the planet are rapidly reduced and prices are naturally growing into petroleum products.

Also, the governments of many countries are striving to become non-volatile, and hydrogen is quite affordable alternative. Today, GM, BMW, Honda, Ford Corporation, etc.

Engine operation on hydrogen: Features of hydrogen ICA

Let's start with the fact that the internal combustion engine on hydrogen in its design is not very different from the usual OH. All the same cylinders and pistons, a combustion chamber and a complex crank-connecting mechanism for transforming a reciprocating movement to a job.

The only thing in the cylinders is burning not gasoline, gas or, but a mixture of air and hydrogen. It is also necessary to take into account the fact that the method of supplying hydrogen fuel, mixing formation and ignition is also somewhat different compared to similar processes in traditional counterparts.

First of all, the burning of hydrogen compared to the oil fuel is distinguished by the fact that hydrogen burns much faster. In the ordinary engine, a mixture of gasoline or diesel fuel with air fills the combustion chamber when the piston almost rose to the NMT (the top dead dot), then the fuel is on the fuel and after that, the gases are put on the piston.

On hydrogen, the reaction proceeds faster, which allows you to move the filling of the cylinder at the time when the piston is already starting to move in NMT (lower dead dot). Also, after the reaction proceeds, the result becomes ordinary water instead of toxic exhaust gases. As can be seen, at first glance, the standard engine is relatively easy to adjust under hydrogen fuel by improving the intake, release and power system, but it is not.

The first problem is how to get the necessary hydrogen. As is known, hydrogen is in the composition of water and is a common element, but it is practically not found in pure form. For this reason, for maximum autonomy to the vehicle, it is necessary to separately put hydrogen installations to "split" water, allowing the motor to eat the necessary fuel.

The idea seems attractive. Moreover, you can even do without an outdoor inlet and create a closed fuel system. In other words, after each time, when the chamber burns the charge, the cylinder will remain water vapor. If this couple is passed through the radiator, condensation will occur, that is, water is formed again from which hydrogen can be reused.

However, to achieve this, an installation for electrolysis (electrolyzer) should be installed on the car, which will separate the hydrogen from water to then get the desired reaction with oxygen in the combustion chamber. In practice, the installation is difficult and expensive, and it is quite difficult to create such a closed system.

The fact is that any internal combustion engine independently of the type of fuel still needs to protect loaded nodes and rubbing pairs. If simply, without the engine oil, it is not necessary to do. At the same time, the oil partially enters the combustion chamber and then in the exhaust. This means that completely isolate the fuel system on hydrogen (not to use the outer air) almost the unrealizable task.

For this reason, modern hydrogen internal combustion engines resemble gas engines, that is, gas aggregates propane. To use hydrogen instead of propane, it is enough to change the settings of such an engine. True, the hydrogen decreases somewhat. However, hydrogen needs less to get the necessary return from the motor. In this case, no installations for autonomous hydrogen production is expected.

As for the attempt to submit hydrogen into an ordinary gasoline or diesel engine, risks and difficulties are automatically arising. First of all, high temperatures and compression ratio may lead to the fact that hydrogen will be reacting with heating elements of DVS and engine oil.

Also, even a small leakage of hydrogen can cause the fuel to get on a preheated exhaust manifold, after which an explosion or fire can occur. So that it does not happen, rotary motors use more often to work on hydrogen. This type of engine is more suitable for this task, since their design involves an increased distance between the intake and exhaust manifold.

One way or another, even taking into account all the difficulties, a number of problems can be circumvented not only on rotary, but even on piston motors, which allows hydrogen to be considered a rather promising alternative to gasoline, gas or diesel. For example, the experimental version of the BMW 750HL model, which was presented in 2000, has a hydrogen engine for 12 cylinders. The unit successfully works on such a stuff and is able to disperse a car to a speed of about 140 km / h.

True, there are no individual plants for the production of hydrogen from water by car. Instead, there is a special tank, which is simply refueling with hydrogen. The stroke reserve on the full tank of hydrogen is about 300 km. After the hydrogen is over, the engine automatically starts working on gasoline.

Engine on hydrogen fuel cells

Please note under hydrogen engines are understood as aggregates working on hydrogen (hydrogen internal engine) and motors that use hydrogen fuel cells. We have already considered the first type above, now let's stop at the second version.

The fuel cell on hydrogen actually represents a "battery". In other words, this is a hydrogen battery with high efficiency about 50%. The device is based on physicochemical processes, in the housing of such a fuel cell there is a special membrane conductive protons. This membrane shares two cameras, in one of which is an anode, and in another cathode.

In the chamber, where the anode is located, hydrogen comes, and oxygen falls into the cathode chamber. Electrodes are additionally covered with expensive rare earth metals (often platinum). This allows you to play the role of a catalyst that has an impact on hydrogen molecules. As a result, hydrogen loses electrons. At the same time, protons go through the membrane to the cathode, while the catalyst also affects them. As a result, a combination of protons with electrons, which come outside.

This reaction forms water, with electrons from the camera with the anode enter the electrical circuit. The specified circuit is connected to the engine. Simple words, electricity is formed, which makes the engine work from such a hydrogen fuel cell.

Such hydrogen engines allows for at least 200 km. On one charge. The main minus is the high cost of fuel cells due to the use of platinum, palladium and other expensive metals. As a result, the ultimate cost of transport with such an engine increases greatly.

Hydrogen engine: Further perspectives

Today, many companies work on the creation of eco-friendly engines. Some go along the way of creation, others make a bet on electric vehicles, etc. As for hydrogen plants, in terms of ecology and performance, this option may also come to compete in gasoline, gas or a diesel population in the near future.

Hydrogen engines showed themselves somewhat better than the most advanced electrocars. For example, the Japanese model Honda Clarity. The only thing remained such a lack of ways and the possibilities of refueling. The fact is that the infrastructure of hydrogen gas stations is not particularly developed, and on a global scale.

Also, the selection of hydrogen cars is not particularly large. In addition to Honda Clarity, it is possible to mention Mazda RX8 Hydrogen, as well as BMW Hydrogen 7. In fact, these are hybrids, which work on liquid hydrogen and gasoline. You can also add to the Mercedes GLC F-Cell list. This model has the ability to recharging from the household power supply and allows you to pass up to 500 km. On one charge.

Additionally, it is worth noting the model Toyota Mirai. The car works only on hydrogen, one tank is 600 km. Hydrogen engines are still found on the domestic model "Niva", and also installed by Koreans for a special version of the Hyundai Tucson SUV.

As can be seen, many manufacturers are actively experimenting with the engine on hydrogen, but this solution still has many drawbacks. At the same time, some disadvantages strongly interfere with the mass promotion.

First of all, this is the safety and complexity of transporting such fuel. It is important to understand that hydrogen is very fuel and explosive even with relatively low temperatures. For this reason, it is difficult to store and transport. It turns out, it is necessary to build special hydrogen tanks for cars with this type of engine. As a result, very little in the practice of hydrogen gas stations.

It is also possible to add certain complexity and high costs for repairing and maintaining a hydrogen unit, as well as the need to prepare and educate a large number of highly qualified personnel. If we talk about the car itself on the hydrogen and its operational characteristics, the presence of a hydrogen installation makes the car heavier, the handling is naturally deteriorating.

Let's summarize

As can be seen, today hydrogen cars and the engine on water can be considered a completely real alternative to not only the usual internal combustion engine, which use oil fuel, but also electrocarars.

First of all, such installations are less toxic, while they do not need expensive oil-based fuels. Also cars with a hydrogen engine have an acceptable stroke. Hybrid models that use both hydrogen and gasoline are on sale.

As for shortcomings and difficulties, the car with a hydrogen engine today has a high cost, and problems may arise with fuel refueling due to the insufficient amount of filling stations. Do not forget about the fact that it is also not easy to find specialists who are capable of high quality and professionally serving a hydrogen power plant. In this case, the maintenance will be quite expensive.

Finally, we note that the active construction of pipelines for pumping Methane gas promises in the future the ability to pump along the same pipelines and hydrogen. This means that in the case of the growth of the total number of cars with hydrogen engines, the likelihood of a rapid increase in the number of specialized filling stations is also high.

Read also

Improvement of the design of the piston engine, the refusal of the CSM: a frightened engine, as well as the engine without crankshaft. Features and prospects.