Total device TNVD BOSCH VE

High Pressure Fuel Pump (TNLD) - the main structural element of the diesel engine injection system, which performs two main functions: dosed fuel supply to the engine cylinders under pressure and determining the correct moment of injection. After the rechargeable injection systems appear, the electronic nozzle is performed.

Schematic diagram of a diesel fuel supply system with a single-slunger distribution fuel pump () with an end cam drive plunger shown in Figure:

Fig. Schematic diagram of the diesel engine of the diesel engine with a unitununger TNVD: 1 - low pressure fuel liner; 2 - thrust; 3 - fuel supply pedal; 4 - TNVD; 5 - electromagnetic valve; 6 - high pressure fuel pipe; 7 - fuel line of the drain highway; 8 - nozzle; 9 - incandescent candle; 10 - fuel filter; 11 - fuel tank; 12 - fuel pumping pump (used in high-length highways; 13 - rechargeable battery; 14 - ignition lock; 15 - control unit for incandescent challenges

The fuel from the tank 11 is hampered by the low pressure fuel supply to the fuel filter of the fuel purification of the fuel 10, from where it is suused with the low pressure fuel pump and is sent to the inner cavity of the TNVD 4 case, where the pressure of about 0.2 ... 0.7 MPa is created. Next, the fuel enters the pumping section of the high pressure and with the help of a plunger - a distributor in accordance with the order of operation of the cylinders is supplied according to the high pressure fifteers 6 in the nozzle 8, as a result of which the fuel is inverted into the diesel combustion chamber. Excess fuel from the TNVD housing, nozzles and fuel filters (in some structures) is merged by fuel lines 7 back to the fuel tank. Cooling and lubricant TNVD are carried out circulating fuel in the system. Filter of fine fuel purification is important for normal and trouble-free operation of the TNVD and the nozzles. Since the plunger, the sleeve, the discharge valve and the elements of the nozzle are the details of the precision, the fuel filter must delay the smallest abrasive particles with a size of 3 ... 5 μm. An important function of the filter is also the detention and decay of water contained in the fuel. Moisture entering the inner space of the pump can lead to the exit of the latter due to the formation of corrosion.

The fuel pump submits to a diesel cylinder strictly dosed amount of high pressure fuel at a certain point in time, depending on the load and speed mode, so the characteristics of the engines substantially depend on the operation of the TNVD.

Scheme and general view of the VE distribution pump

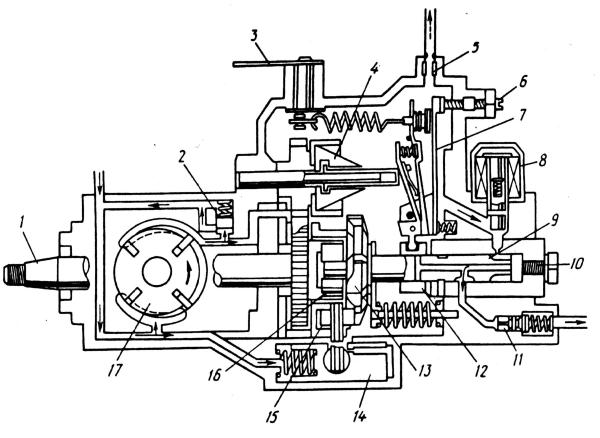

The VE distribution pump circuit is presented in the first drawing, and its general view is as follows.

The main functional blocks of the VE fuel pump are:

- rotary-blade low pressure fuel pump with regulating bypass valve

- high pressure unit with distribution head and dosing coupling

- automatic rotational speed controller with levers and springs

- electromagnetic locking valve that turns off the fuel supply

- automatic device (automatic) Changes in the fuel injection advance

Fig. Fuel pump diagram - Bosch VE: 1 - pump drive shaft; 2 - bypass valve of internal pressure regulation; 3 - fuel control lever; 4 - cargo regulator; 5 - fuel plum jacker; 6 - Full load adjustment screw 7 - transmission lever of the regulator; 8 - electromagnetic motor stop valve; 9 - Plunger 10 - Central plug; 11 - discharge valve; 12 - dosing coupling; 13 - cam disk; 14 - fuel injection promotion machine; 15 - roller; 16 - coupling; 17 - Low Pressure Fuel Pump

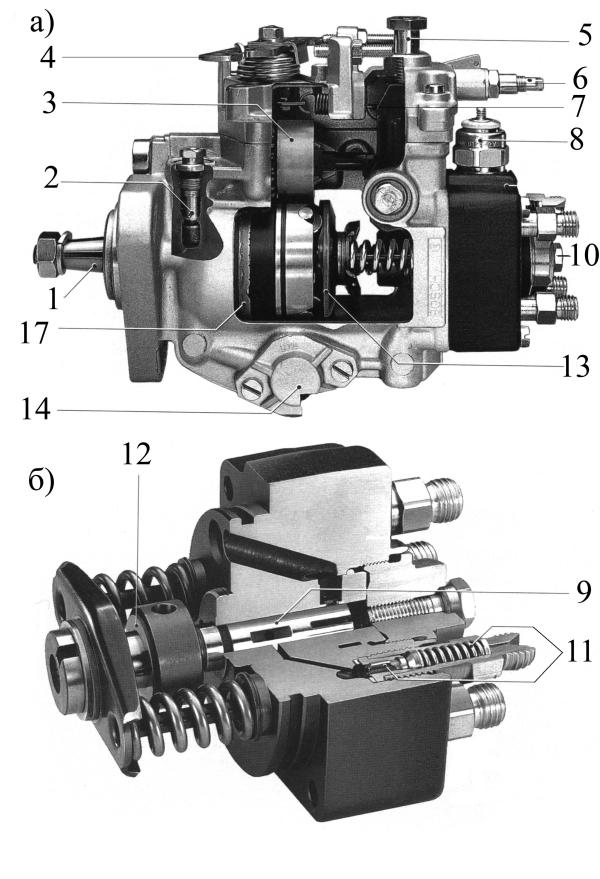

Fig. General view of the distribution pump VE: A - TNVD; B - high pressure unit with distribution head and dosing coupling. Positions correspond to positions on the previous figure.

Additional devices for distribution pump ve

The camshaft VE may also be equipped with various additional devices, such as fuel-feeder or cold start accelerator, which allow you to individually adapt TNLD to the features of this diesel.

The fuel pump drive shaft is located inside the TNVD case, a low-pressure fuel pump rotor 17 and a regulator shaft drive gear gear with loads 4. Behind the shaft 1 stationary in the pump housing is set by a ring with rollers and a fuel injection groove machine 14. Shaft drive TNVD is carried out from the crankshaft of diesel, gear or belt transmission. In four-stroke engines, the frequency of rotation of the TNVD shaft is half of the rotational speed of the crankshaft, and the operation of the distribution pump is carried out in such a way that the progressive movement of the plunger is synchronized with the movement of the pistons in the diesel cylinders, and the rotational provides the distribution of fuel in the cylinders. Progressive movement is provided by a cam washer, and the rotational - the fuel pump shaft.

The automatic regulator of the rotational frequency includes centrifugal loads 4, which through the controller clutch and the lever system affect the dosing coupling 12, thus changing the magnitude of the fuel feed depending on the speed and loading modes of the diesel engine. The TNVD body is closed on top of the lid, in which the axis of the control lever associated with the accelerator pedal is installed.