Diesel engine low pressure fuel pump: main features and purpose

The engine of a car is often compared to the human heart. And there is indeed a certain similarity. Thanks to the heart, a person can live, and a car, thanks to the engine, can move. The heart pumps blood in the body - ensures its circulation to all key organs. In the engine, this function is performed. Today we will consider the features and purpose of the low pressure pump. This element is a very important part of the high pressure fuel pump, necessary for supplying fuel to the high pressure fuel pump. Often it is installed next to the injection pump. Both mechanisms are connected by pipes through which circulation is carried out. At the same time, the fuel passes through filters, where it is cleaned.

What tasks does TNND solve in the fuel system

The low pressure fuel pump of a diesel engine solves an important task. Fuel that is supplied under low pressure is subject to boiling. As a result, vapor locks are formed. Vapor bubbles of light fractions and thicker fuel are separated. This means that a liquid will begin to enter the low pressure pump, the viscosity of which is constantly changing. There is no need to talk about injecting fuel with the help of a high-pressure fuel pump in normal mode. The torch is constantly changing and will not fall into normal parameters.

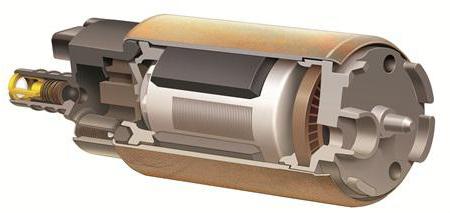

How TNND works

The low pressure fuel pump of a diesel engine consists of a drive shaft. Pumping is carried out using a special rotor, on which there are blades. The design also includes a stator, a distribution disk and a drive gear. When the rotor is driven, its blades approach the stator. Then the formation of chambers is performed due to the influence of centrifugal force. Since voltage is created in the pump cavity, fuel flows from them directly to the injection pump. To do this, there are channels in the distribution disk. A small amount of diesel will enter the reduction valve if the pressure is greater than necessary.  Both devices are interconnected, so a special drain throttle is used to create and maintain the desired conditions. This is a jet that is screwed into the high pressure pump. This creates conditions in the chambers, depending on the speed at which the drive shaft rotates.

Both devices are interconnected, so a special drain throttle is used to create and maintain the desired conditions. This is a jet that is screwed into the high pressure pump. This creates conditions in the chambers, depending on the speed at which the drive shaft rotates.

Booster pump device

The low pressure booster or fuel pump (TNND) in diesel power units has a simple design. It consists of two gears that are constantly engaged with each other. As the teeth rotate, these gears create a flow of fuel through the fuel system to the high pressure pump. The main structural element in a pump-type pump is a piston that pumps fuel. To supply a diesel engine, two modes of operation of the piston are required. This is a working move and an auxiliary one.

Varieties of TNND

The diesel low pressure fuel pump is just one variation of these mechanisms. In addition to diesel, these devices can be found in other engines, regardless of the engine model or year of manufacture. You can’t do without a pump - it is necessary to supply fuel from the fuel tank and transfer it further through the system.  In the case of carburetor gasoline engines, relatively weak mechanical pumps are used. On units equipped with an injection power system, as well as on diesel power units, an electric diesel fuel pump is used.

In the case of carburetor gasoline engines, relatively weak mechanical pumps are used. On units equipped with an injection power system, as well as on diesel power units, an electric diesel fuel pump is used.

Mechanical low pressure fuel pump

This system is installed directly on the cylinder block and is fixed with ordinary screws. The operation of such a pump is ensured by means of a crankshaft with an eccentric. If you press on the eccentric cam, contractions are created inside. So the fuel is supplied through the power system. To prevent fuel from getting back, the pump is equipped with a special valve. The rest of the cam push sends gasoline to the carburetor. If a mechanical-type low-pressure fuel pump is installed in the car, then it is easy to start the engine with it, even taking into account a long downtime. To do this, simply manually pump the swap mechanism.

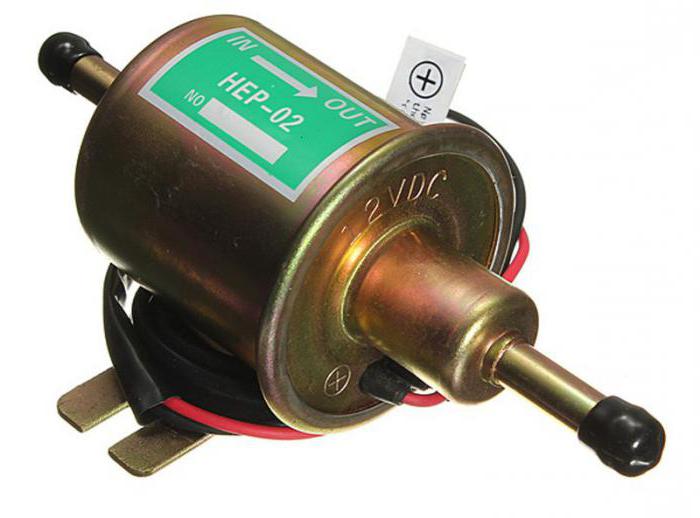

Electric

On modern cars, an electric low-pressure fuel pump is used for a diesel engine and a gasoline injection engine. The use of a mechanical device became simply impossible. He, due to the lower power, could not cope with the tasks. It does not create the necessary pressure inside the fuel system.  In a simpler form, the device is the pump element itself and enclosed in one housing. There is also a fuel filter, a fuel intake and a fuel consumption sensor. The scheme and principle of operation are similar to the algorithm of the unit. The only difference is that an electric motor is used to pump the liquid. In gasoline engines, the high pressure fuel pump is located directly inside the fuel tank. Most car owners are sure that this is not entirely safe. In fact, there is no danger in this. In the case of gasoline, the fuel in the pump is prone to overheating due to the heat generated by the engine. On electrical counterparts, this problem is completely absent. Fuel moves without interruption through the pipes of the system and does not allow the pump to overheat to a critical point. In diesel engines, an electric injection pump is often combined with an injection pump. This can be explained by the need to supply fuel constantly. This ensures stable operation of the engine at various speeds.

In a simpler form, the device is the pump element itself and enclosed in one housing. There is also a fuel filter, a fuel intake and a fuel consumption sensor. The scheme and principle of operation are similar to the algorithm of the unit. The only difference is that an electric motor is used to pump the liquid. In gasoline engines, the high pressure fuel pump is located directly inside the fuel tank. Most car owners are sure that this is not entirely safe. In fact, there is no danger in this. In the case of gasoline, the fuel in the pump is prone to overheating due to the heat generated by the engine. On electrical counterparts, this problem is completely absent. Fuel moves without interruption through the pipes of the system and does not allow the pump to overheat to a critical point. In diesel engines, an electric injection pump is often combined with an injection pump. This can be explained by the need to supply fuel constantly. This ensures stable operation of the engine at various speeds.

High pressure fuel pump (TNVD)

This device is considered one of the most complex in a diesel engine. Its main task is to ensure the supply of diesel to the combustion chambers under the supply is provided not just under a certain pressure, but at the required time. The portion is very accurately measured by electronics and fully corresponds to the level of load on the unit. There are several types of injection devices. These are units with a battery injection system and with direct action.  The device in which the direct principle of operation is used is different in that the design uses a plunger equipped with a mechanical type of drive. So, injection and injection are performed simultaneously. A separate section of the pump sprays its own dose of fuel into each combustion chamber. The necessary pressure is provided by the movement of the plunger mechanism.

The device in which the direct principle of operation is used is different in that the design uses a plunger equipped with a mechanical type of drive. So, injection and injection are performed simultaneously. A separate section of the pump sprays its own dose of fuel into each combustion chamber. The necessary pressure is provided by the movement of the plunger mechanism.

Battery injection pumps and their features

Pumps equipped with battery injection are different. So, the working drive of the plunger will be affected by gases compressed under pressure in the engine cylinders. Also, the impact can be exerted with the help of springs. Today, devices with a hydraulic type accumulator are common. They are installed in powerful motors, operating mainly at low speeds.

The main malfunctions of high pressure fuel pumps

The main problem is the decrease in the performance of the device and the drop in the injection level, which was provided by the low pressure fuel pump of the diesel engine. You can determine it using a pressure gauge or a pressure sensor that is installed at the inlet.  Most often, the reasons for the decrease in the performance of high pressure fuel pumps are clogging and jamming of the working element. As for the first reason, diesel fuel may contain various impurities, which, although they pass through the filter elements, nevertheless accumulate in the valve. It is also possible that the elasticity of the return spring of the element has decreased.

Most often, the reasons for the decrease in the performance of high pressure fuel pumps are clogging and jamming of the working element. As for the first reason, diesel fuel may contain various impurities, which, although they pass through the filter elements, nevertheless accumulate in the valve. It is also possible that the elasticity of the return spring of the element has decreased.

How to repair TNND

If the efficiency of the unit has fallen, the low-pressure fuel pump of the diesel engine must be dismantled and inspected. Often, productivity increases again after washing and cleaning the working cavities and elements of the device.  It will also be useful to drain debris and resin from the drainage compartments. For more serious repairs, repair kits are used, which are now produced in Chinese factories that manufacture spare parts for car engines.

It will also be useful to drain debris and resin from the drainage compartments. For more serious repairs, repair kits are used, which are now produced in Chinese factories that manufacture spare parts for car engines.

Knowing how the low-pressure fuel pump of a diesel engine works, the principle of operation of the device, you can easily repair it or replace it.