VAZ 2106 carburetor device

The car VAZ 2106 is a sample of the classic automotive European design and design solutions of the middle of the twentieth century. Like everything in this car, and the engine, and the gearbox, and the grip, has become native for a huge army of fans of classic Zhiguli. However, such complex devices and nodes, like a carburetor, require a more detailed study than today and we will deal with.

Features of the supply system VAZ 2106

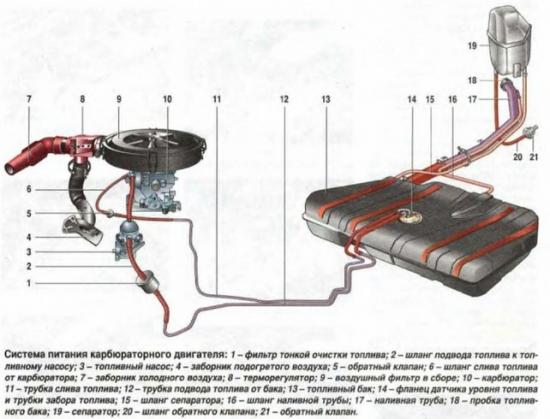

The supply system of the car VAZ 2106 is arranged according to the standard scheme, which was used on all carburetor cars of the last century. The fuel from the tank is served on copper benzing in the engine compartment. The pressure necessary for supplying the fuel creates a membrane type, which is driven by an eccentric cam movement. The fuel is cleaned from large fractions with a mesh filter in a gas tank, as well as in, however, as practice has shown, this is completely insufficient for smooth operation of the carburetor.

Therefore, almost all the owners of classical zhiguli set additional filters of fine cleaning directly at the inlet to the carburetor. These filters are usually made of transparent plastic, which allows you to control the degree of contamination of the mesh or corrugated filter element.

Model range of carburetors for VAZ 2106

The carburetors of different models were installed on the VAZ 2106. As a rule, cars from 1974 to 1976 releases were equipped with a carburetor of the DAAZ model 2103-1107010-01. This is a licensed copy of Weber carburetor. Structurally carburetor did not differ from the carburetor of the car VAZ 2101, but had several other target parameters that we led in the table.

Later, when in the design of the ignition system began to apply a vacuum corrector for the ignition angle, the design of the carburetor was changed. Factory index of the ozone carburetor - 2107-1107010-20. Cars that were completed by the old sample rubber, without a vacuum corrector of the ignition advance, were equipped with exactly the same carburetor, but without a tube, which connected the intake manifold and the vacuum adjustment mechanism on the rubber. Model of such a carburetor - 2107-1107010-10.

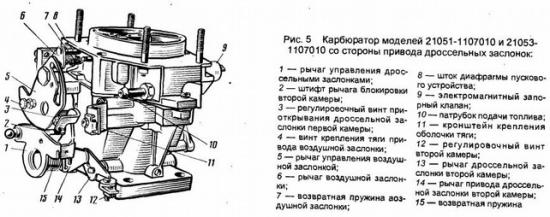

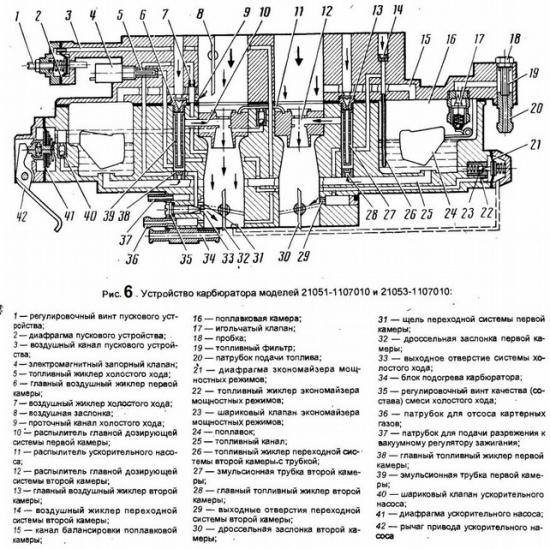

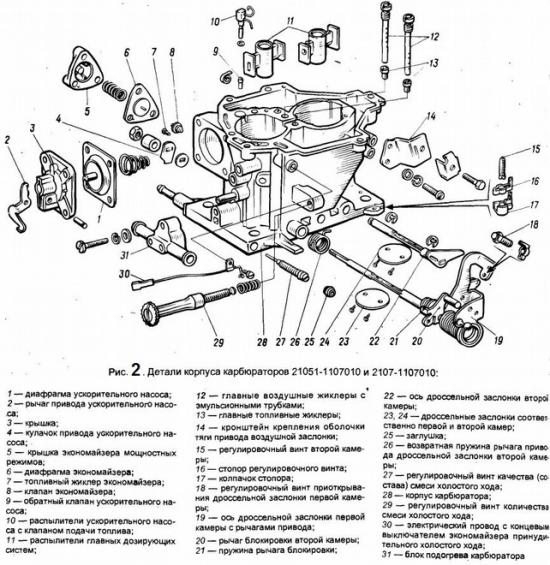

The VAZ 2106 carburetor device is given on the branded Togliatti poster, which we have placed on the page. There is nothing archent in the device of the karbyurator, but about work and, most importantly, the adjustments of some of the main parameters of this carburetor should be said separately. The main systems of the ozone karburator:

- autonomous XX system;

- pneumatic diaphragm type launch device;

- acpercelative pump, also pneumatic diaphragm type;

- economyman with a pneumatic receipt;

- transition systems that ensure the smooth operation of the secondary chamber;

- carter ventilation system.

Despite a pretty primitive device, the carburetor showed itself in all modes of engine operation. However, the main systems require adjustments to achieve optimal power, economical and dynamic engine characteristics.

Principle of operation and maintenance

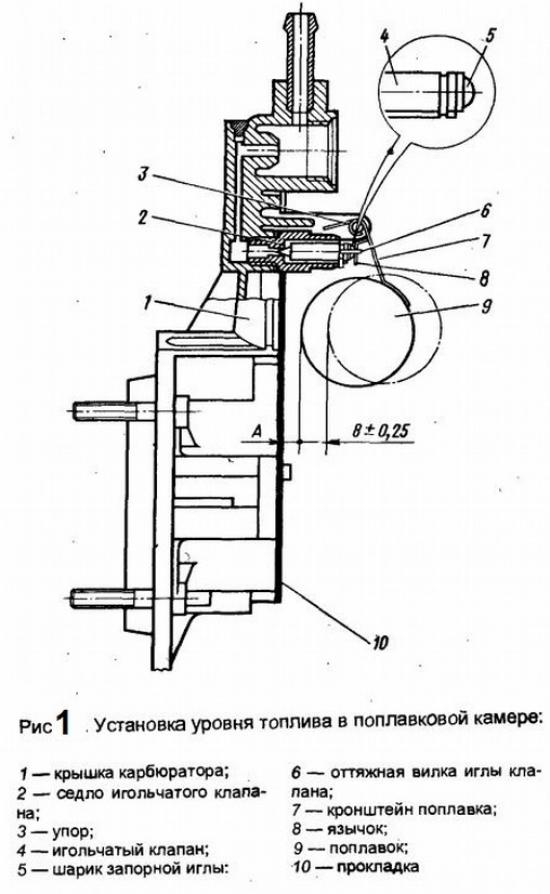

One of the main adjustments of the ozone carburetor remains adjusting the fuel level in the float chamber. The level affects both engine economic indicators and accelerating dynamics, start and operation in high revolutions. With an insufficient level of fuel in a float chamber, the engine will work on a depleted mixture, which will affect the stability of revolutions in transient modes, as well as the motor will not be able to develop a passport power, will not be enough fuel.

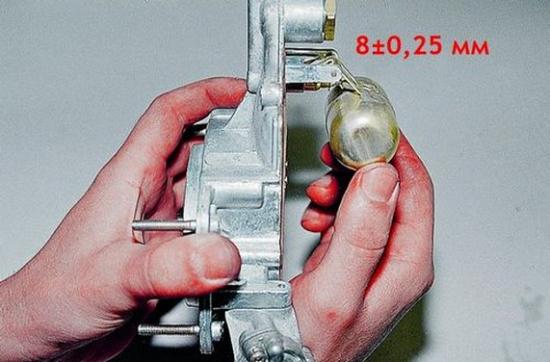

To determine the correct level in the float chamber, it is necessary to dismantle the air filter with the housing and the top cover of the carburetor. The passport gap between the float and the laying plane of the carburetor cover should be not more than 6.5 mm. The clearance adjustment is made by flexing the tram of the float (a), which during the measurement should barely touch the ball of the needle valve.

In this case, it is necessary to check the tightness of the valve. To do this, it is enough to create a discharge in the tube, put on the fitting or mouth or pear. If the tightness of the valve seat is broken, the replacement is subject to the needle of the valve along with the saddle. They are sold both in Repair Kit and separately. If the tightness of the valve is good, it remains only to check the free flow of the float. It should be at least 8.5 mm.

Having mastered the main methods for adjusting the carburetor VAZ 2106 and its design, you can achieve an optimal consumption of fuel, satisfactory acceleration dynamics and optimal engine power. And when working with ozone carburetors, it is enough to examine the scheme and device of the node, then the adjustment, cleaning and replacement of loopholes, gaskets and diaphragms will not make much difficulty. Good luck on the roads, stable operation of the engine and high-quality fuel!