Diy galvanizing of a car body and galvanizing of viburnum

There are many ways to protect your vehicle from the harmful effects of corrosion. One of them is body zinc plating, which has been used in foreign countries for over 30 years. Domestic production also does not stand still and is gradually introducing this technology. But most used cars do not have such protection, so the question of self-galvanizing the body, or at least its most vulnerable elements, is quite reasonable.

Description of body galvanizing and its advantages

What is a galvanized car body? At first glance, everything is quite simple. Galvanizing is the coating of a metal surface with a zinc-containing substance that is intended to limit the effects of destructive corrosion. The difficulty lies in the fact that galvanizing the body is not as easy as it seems. It is relatively expensive, troublesome and technologically difficult.

However, galvanizing is still used and is constantly evolving, this is especially typical for foreign automotive companies, which have been covering their cars with a protective compound for more than a decade. This attention to galvanizing can be attributed to the benefits that the car body receives after appropriate treatment.

The main advantage is corrosion resistance. The zinc layer itself does not react in any way to the effects of moisture and salts, which constantly attack the metal. It creates a barrier that protects steel from the destructive effects of an aggressive environment.

In addition, the advantages include the durability of such a coating. No other anti-corrosion treatment can match the durability of zinc plated products.

Briefly about the factory galvanized car

Many car manufacturers already zinc their car bodies at the production stage. Some undergo this treatment completely the entire body. Others only zinc some elements. There are also those that process several parts completely, and the rest only on one side. For example, the bodies of the domestic Lada Kalina and some models of European manufacturers are subjected to such processing.

Today, the manufacturer guarantees that during the production of Kalina, about 40% of the entire surface of body parts is galvanized. Some of them are processed by full immersion in an electroplating bath. Others, less vulnerable, are covered only from the inside, where there is no full-fledged paintwork. The manufacturer claims that those elements of Kalina that are not galvanized are protected with a layer of primer. In addition, rotting of the inner part of the body is much more difficult to detect, so the main emphasis is on them.

In addition to Kalina, it is worth citing as an example several foreign models, which are also fully or partially galvanized. Among them, the following models can be distinguished:

- Many models are treated with a thermal galvanizing method;

- Volvo;

- some Ford models;

- Audi and the manufacturers below use galvanized galvanizing of their vehicles;

- Honda;

- Alfa Romeo;

- Mercedes;

- Peugeot;

- Toyota and others.

Some of the above manufacturers have galvanized the entire body of their models. This adds significant value to them, however, and their service life increases significantly.

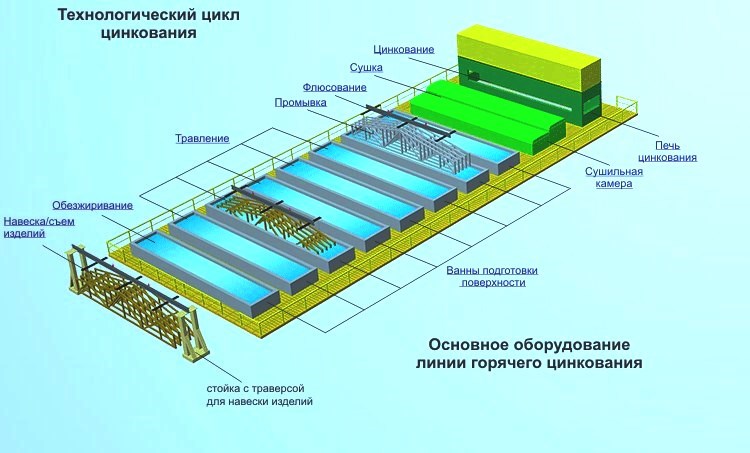

Car body galvanizing methods

Separately, a few words should be said about the methods of galvanizing a car. There are three main methods used here:

- Thermal - consists in immersing the body in a container with a special zinc-containing solution, which is heated to a certain temperature;

- Galvanic - a part or body is completely immersed in a bath with zinc dissolved in it. The part itself is connected to the negative electrode, and the container body to the positive one. Thus, the positively charged zinc particles attach to the body metal;

- Cold galvanizing is very similar to the previous method. However, the part is not immersed in the container, but is treated with a zinc-containing electrode, which is also connected to the positive terminal of the power source.

The last two methods are often used to galvanize a car body with your own hands at home. At the same time, independent galvanic treatment is used much less often due to its complexity and high cost. These methods should be considered in more detail, since they are quite realistic to carry out with your own hands in a garage.

Preparation of zinc plating solution

Galvanizing a car body by such methods begins with the preparation of a zinc-containing solution. This will require sulfuric acid and pure zinc. All of this can be bought in the car market or in amateur radio stores. You will also need a power source - a regular car battery or charger will do. You will also need a container of the appropriate size, resistant to acid.

To prepare a zinc-containing solution, you need to put a piece of zinc in a prepared container at the rate of about 400 g of metal per 1 liter. Further, acid is poured into the container in small doses. In this case, you should adhere to safety precautions - it is imperative to protect your eyes, respiratory organs and hands.

When the zinc dissolves, it will be necessary to make sure that the acid has completely reacted, for which another piece of zinc should be added to the resulting solution.

If no bubbling reaction is observed, then the solution can be considered ready for use. The resulting composition can be used both for the galvanic method of galvanizing with your own hands and for the cold one. How to do this is described in a few words below.

Small part galvanized

The vehicle part to be machined is prepared accordingly. Traces of corrosion and old paintwork are removed. When cleaning, do not use aggressive paint removers. If, nevertheless, it was not possible to do without them, then the part should be treated with an aqueous solution of soda.

Next, the required amount of zinc-containing solution and the corresponding container are prepared. The negative terminal of the battery is connected to the part, and it is immersed in the solution. The container itself is connected to the positive terminal and voltage is applied. For successful galvanizing of a small part, a voltage of 12 V and a current of about 1 A. The result of processing should be a part with a uniform gray coating. Next, the element is removed and thoroughly rinsed in an aqueous solution of soda.

Zinc plating of large parts

For the processing of large parts, the cold galvanizing method is used. To implement it, you will need the previously described solution and an electrode with a piece of zinc at the end. The electrode is wrapped in a rag and connected to the positive terminal of the power source. The part itself is connected to the negative terminal of the battery.

The whole process of galvanizing with your own hands is reduced to the following - the electrode is moistened with a prepared solution and the metal is already processed by it until a uniform gray zinc layer is obtained.